Difference between revisions of "User:Thebastidge"

Thebastidge (talk | contribs) (→Requirements Analysis) |

Thebastidge (talk | contribs) (→Requirements Analysis) |

||

| Line 47: | Line 47: | ||

* Modular/Scalable | * Modular/Scalable | ||

| + | Here is a link to a tool for calculating hexgon dimensions for purposes of comparing scale: [https://rechneronline.de/pi/hexagon.php Hexagon Calculator] | ||

** Able to scale by adding hexagons until a "honeycomb archipelago" is achieved. Can make multiple lagoons. | ** Able to scale by adding hexagons until a "honeycomb archipelago" is achieved. Can make multiple lagoons. | ||

** [[User:DanB/BaseStead_Strategy]] | ** [[User:DanB/BaseStead_Strategy]] | ||

Revision as of 15:30, 29 August 2017

Larry is a network engineer working for a major US Electric Utility. He has been a TSI forum member from the inception.

Contents

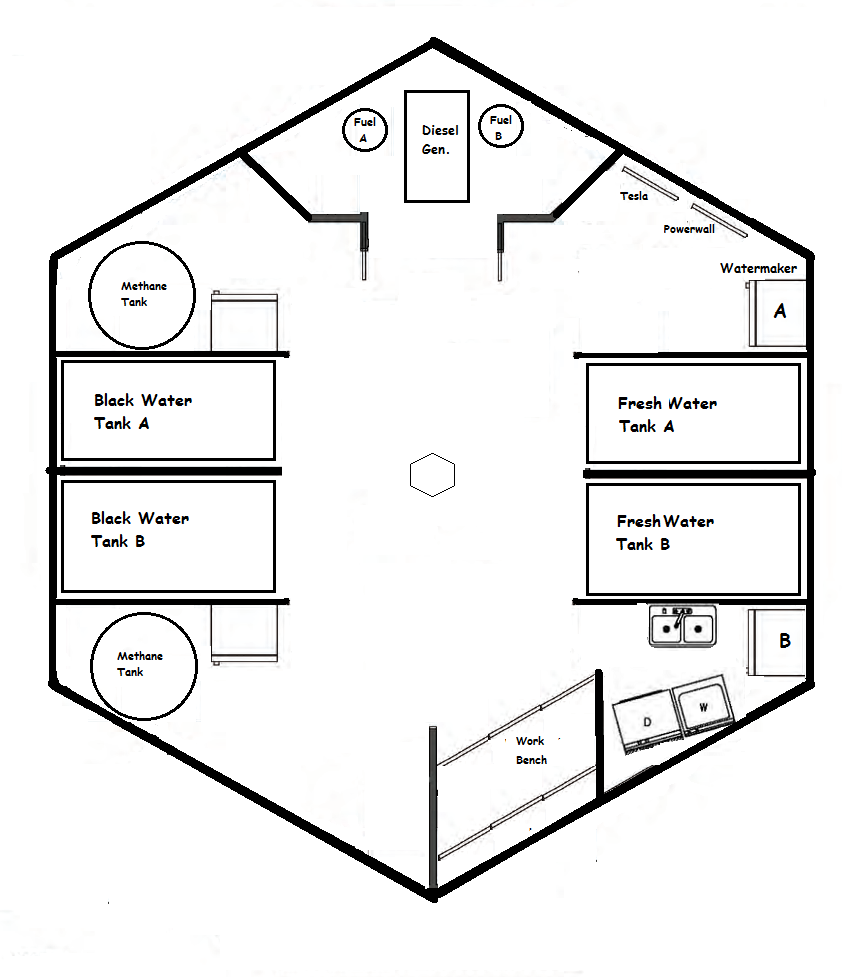

Architectural Description: Hexstead

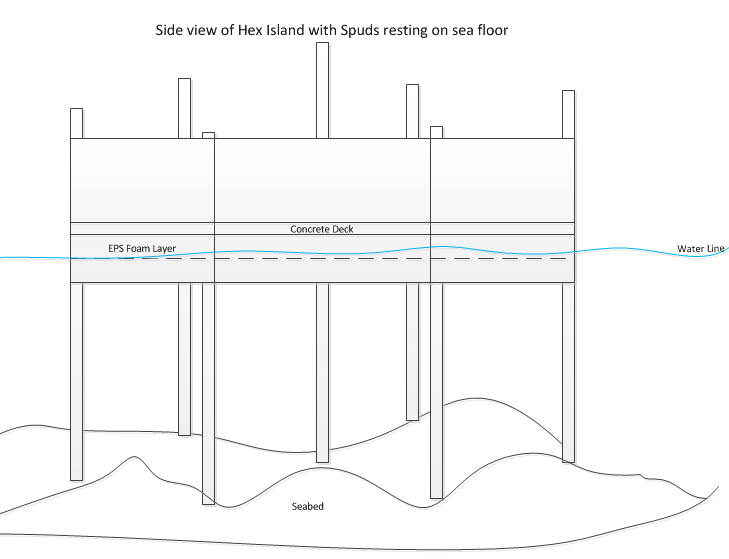

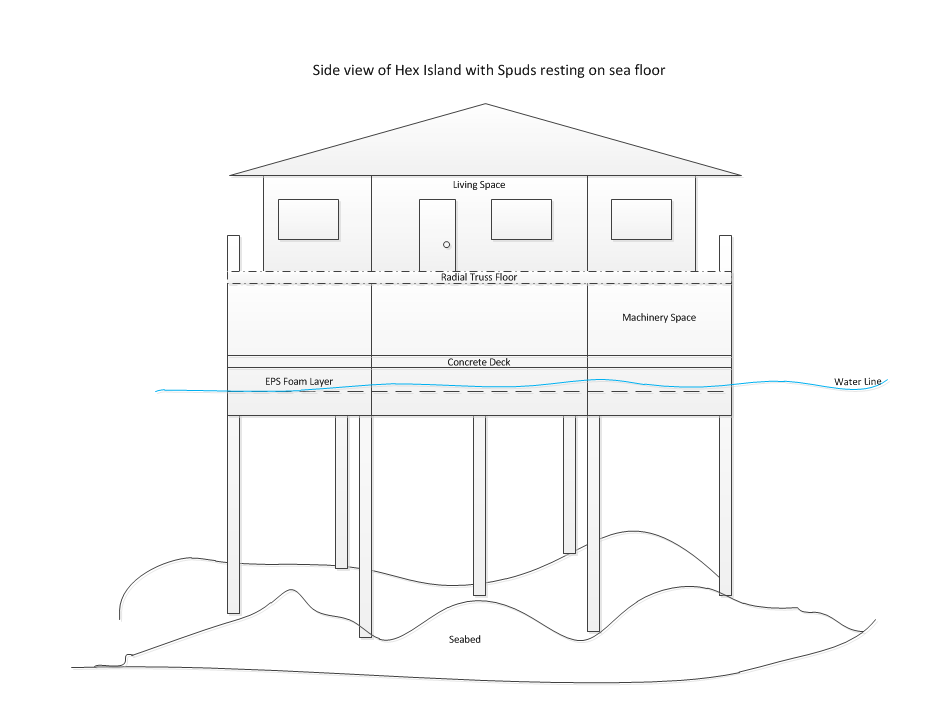

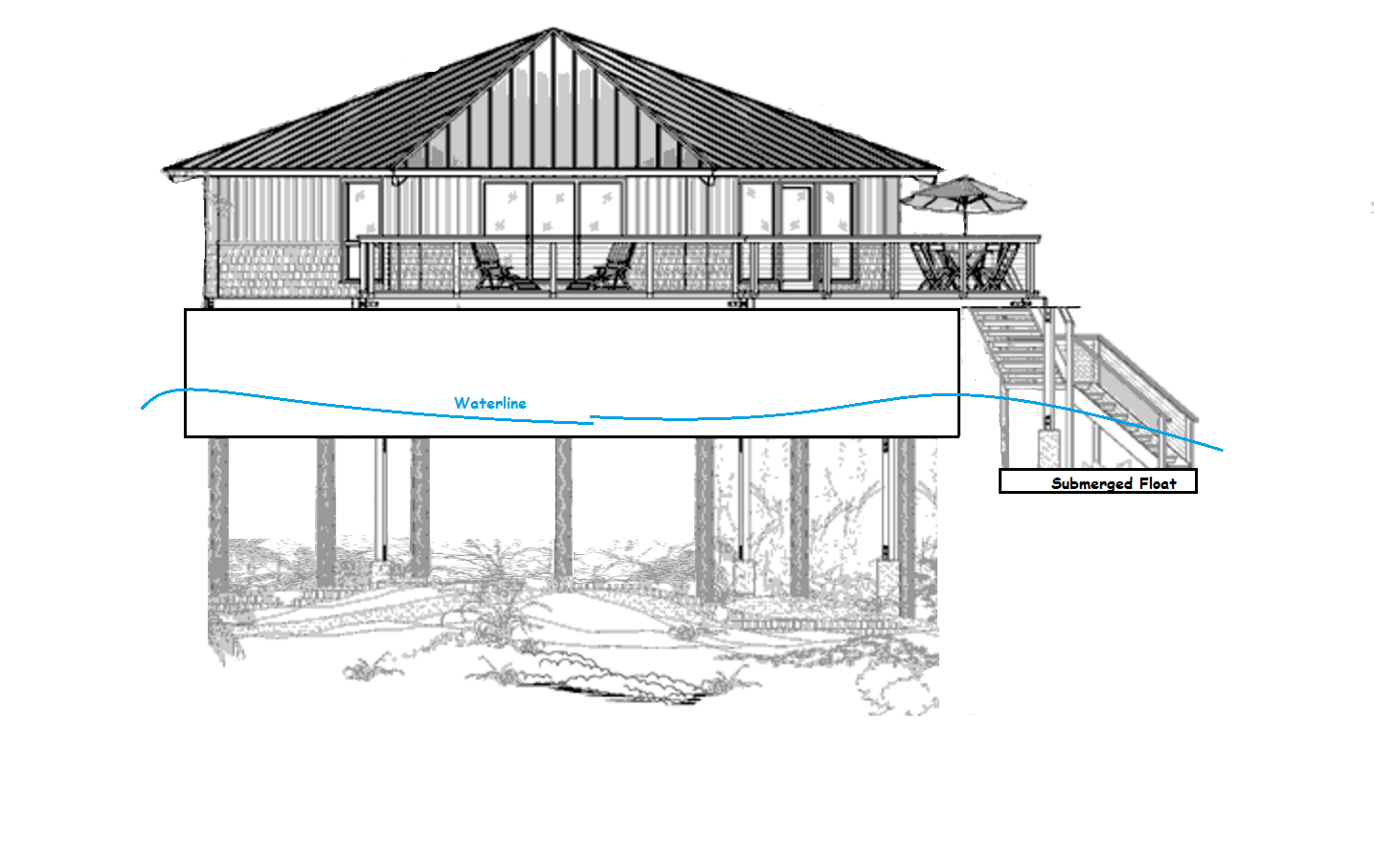

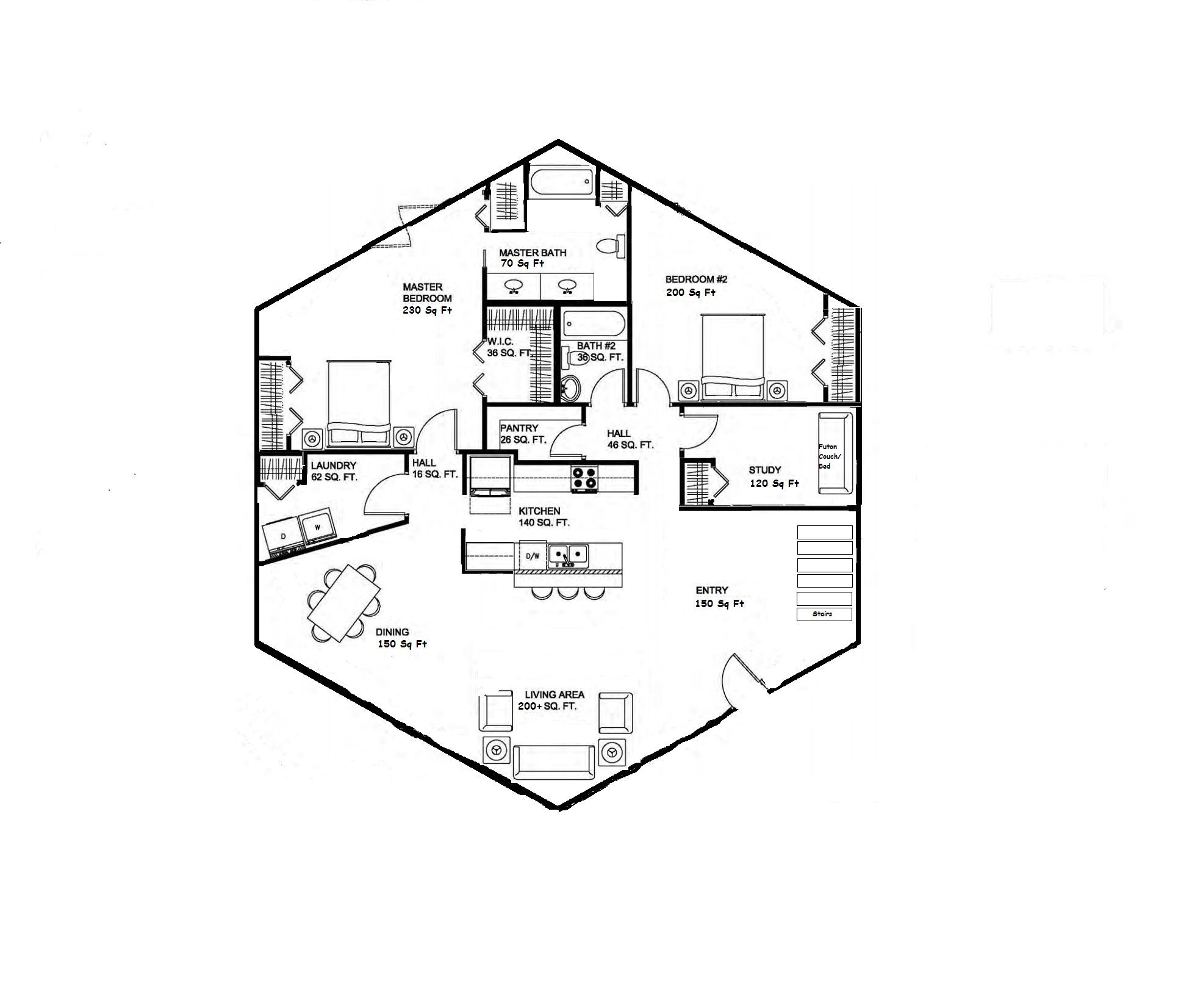

The Hex Habitat concept is a semi-submersible, gravity-based structures (artificial island based upon a spud barge design with variable bouyancy) to be floated into place and then lowered to seafloor contact for semi-permanent or permanent mooring. Each Habitat is constructed as a hexagon approximately approximately 8 meters per side, 10 meter height for emplacement in 3-10 meter depths. The hexagonal hull is characterized by a submerged skirt surrounding a displacement cavity filled with Expanded Polystyrene Foam (EPS or “styrofoam”), internal deck, and an above-water bulwark containing interior space. The internal deck forms the bottom of the water-tight hull and the top of the displacement cavity. An upper deck based upon a radial truss design forms the “weather deck” and serves as floor for living space enclosed by superstructure. (See LightTopHull) The skirt, internal deck, and bulwarks are made of basalt-fiber-reinforced alumino-silicate geopolymer1 concrete, a material with significant structural strength and longevity, as well as favorable chemical composition for providing coral and shellfish substrate. The internal deck is permanently supported by buoyant blocks of sealed EPS foam in the displacement cavity. The skirt walls extend below the waterline and permanently contain and protect the EPS foam from mechanical wave action and ultraviolet (UV) degradation, as well as providing last resort defense (as legs) against complete submersion should the spuds fail.

At each angle of the hexagon, an integral spud well extending the vertical distance from the top of the bulwark to the bottom of the skirt holds the spuds. Hydraulic lifting mechanisms temporarily mounted above the spud wells during deployment serve to extend reinforced concrete spuds downward to the sea floor. These spuds act as legs for leveling the platform and then are subsequently locked into place, but may be adjusted from time to time as needed if the sea floor depth should change due to scouring or settling, etc.. A seventh spud well is centered in the structure and serves to support both the lower and weather deck. The deck and center of the hexagon remains supported by buoyant EPS foam blocks even after gravity placement, resulting in near complete elimination of dead load. The internal deck is elevated to a minimum of 1 meter over mean high tide and the weather deck is approximately 3 meters higher. The weather deck supports a second story of habitable or occupied work space in some Hex Habitats. Dead load on the spuds is minimized by the same technique of buoyant EPS foam placement that minimizes dead load on the deck. The depth should be adjusted such that the weight of the internal deck is neutralized by buoyant foam, the weight of the walls rest on the spuds, and the spuds rest on the sea floor. The amount of gravity loading on the spuds thus achieved is calculated to exceed 100 year storm levels of lateral loading on the Hex Habitat hull in the target location.

It is important to note "Fatigue damage of a structure is caused by fluctuating loads that occur during the structure’s service life. For offshore structures, the most dominant source of fluctuating load is waves. "

Detail

- Material issues - geopolymer concrete reinforced with basalt fiber, EPS foam inside base. Since it does not go far below the water, foam and concrete should be ok. With foam, cracks in the concrete will not be fatal. The wall could be somewhat like the one at this page.

- Fiber Reinforcement is basalt fiber and basalt rebar.

Requirements Analysis

- Safety

- It is very wide compared to typical yachts and symmetrical in all directions and so should be very stable

- Base is filled with foam so essentially unsinkable. If spud legs fail, the hull maintains buoyancy.

- Bulwarks tall enough for storm surge/extreme high tides

- No active ballast controls necessary

- Spud Deployment Safety Issues

- Comfort

- Broad spaces, no vertical hull curvature to limit options

- Extremely stable when legs are lowered/hull raised to provide gravity base

- Can emulate natural islands- bio-mimetic design

- Provides more psychological comfort than typical "built environment"

- Access to water level is a convenient ramp or flight of stairs

- Attractive Design

- Concrete dyes and stains available to color the walls

- Stamped/molded design built into concrete bulwarks for more natural look

- Superstructure built like a round house

- Radial truss floors allow for very open floor plan with no internal bearing walls

- Stilt homes already a familiar design

- Cost

- Depends on size. 24'/side (nearly 1500 sq ft per level x 2 levels for ~3000 sq ft total) estimate comes to ~$300,000 USD fully finished

- Smaller sizes (up to 24'/side) simplify the slab construction of the internal deck

- Modular/Scalable

Here is a link to a tool for calculating hexgon dimensions for purposes of comparing scale: Hexagon Calculator

- Able to scale by adding hexagons until a "honeycomb archipelago" is achieved. Can make multiple lagoons.

- User:DanB/BaseStead_Strategy

- Free Floating

- Deploys by tug tow as a floating "barge"

- Option to use gravity base mooring on "spud" legs.

- Design Considerations for Transport of Jackup Platforms on Barges

- Standards

- Guide for Building and Classing Accommodation Barges

- Guide for Portable Accommodation Modules

- Guide for Habitability of Industrial Personnel on Accommodation Vessels

- Rules for Building and Classing Offshore Installations

- Facilities Offshore Installations (2016)

- Facilities on Offshore Installations (2017)

- Floating Production Installations (2017)

- Crew Habitability on Offshore Installations

- GUIDE FOR BUILDING AND CLASSING GRAVITY-BASED OFFSHORE LNG TERMINALS

- Fatigue Assessment of Offshore Structures

- Review and Approval of Novel Concepts

- Risk Evaluations for the Classification of Marine-Related Facilities

- Surveys Using Risk-Based Inspection for the Offshore Industry

- Subsea Riser Systems

- Dynamic Analysis Procedure for Self-Elevating Units

- BUCKLING AND ULTIMATE STRENGTH ASSESSMENT FOR OFFSHORE STRUCTURES

- Guide for Building and Classing Mobile Offshore Units

- Environmental Protection Notation for Offshore Units, Floating Installations, and Liftboats

- Crew Habitability on Mobile Offshore Drilling Units (MODUs)

- Implementation of Human Factors Offshore Installations

- Guidance Notes on Structural Analysis of Self-Evaluating Units

- Guidance Notes on Design and Installation of Dynamically Installed Piles

- Guide for Certification of Offshore Access Gangways

- Guide for Dropped Object Prevention on Offshore Units and Installations

- Guidance Notes on Conversion of Mobile Offshore Drilling Units to Floating Production Installations 2017

- Guide for Conversion of Self-Elevating Units to Offshore Installations 2017

- Mobile

- Semi-mobile. Can be towed into place across significant distance, but once connected into honeycomb archipelago, movement becomes less practical.

- Draft

- Shallow draft compared to cargo vessels- ~9ft/3m

- Spud legs can be 30+ meters

Diagrams and Architectural Sketches

Videos of model tests

None yet.