User:Vincecate/GeodesicVessel

Contents

External

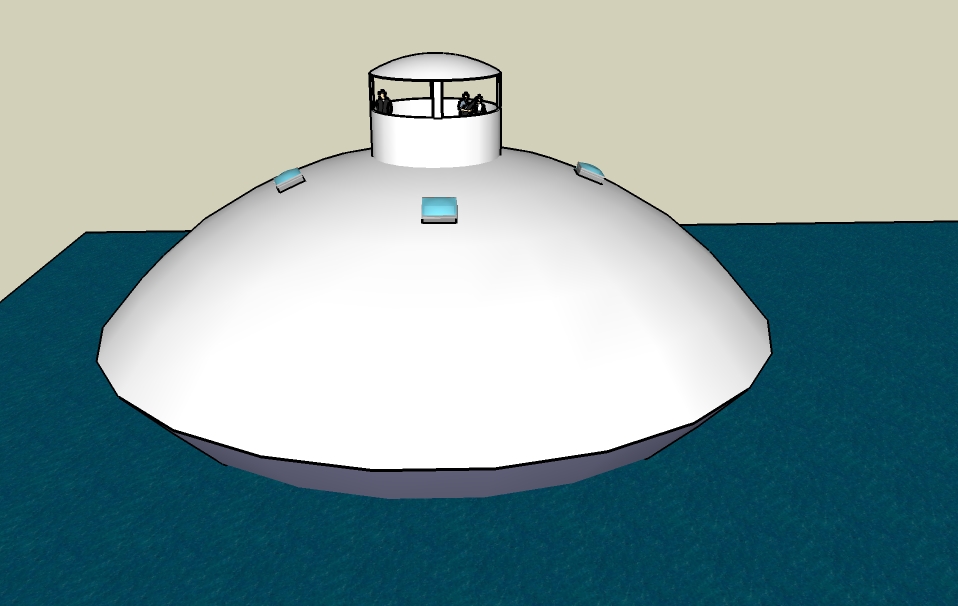

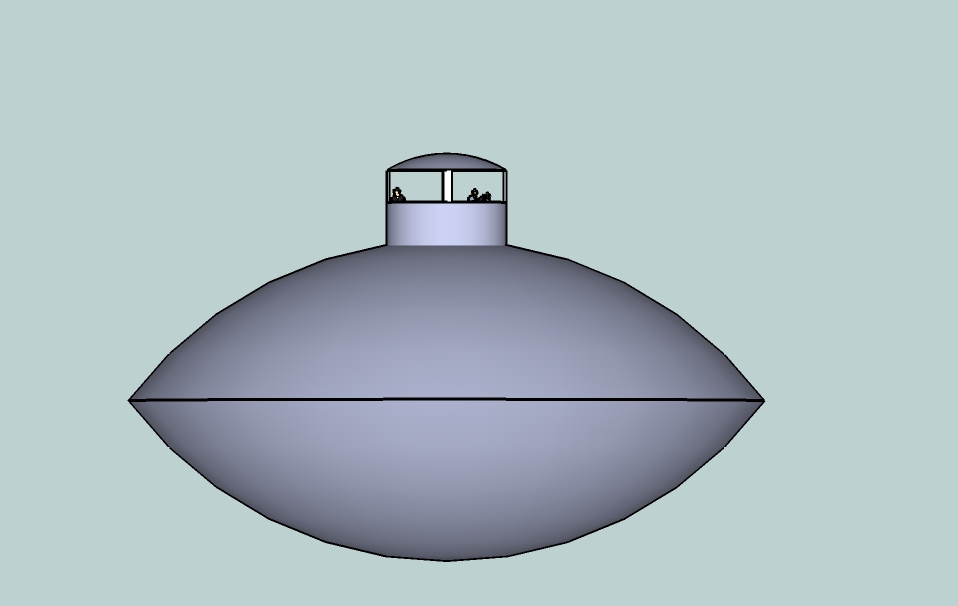

Idea is that both a hull and roof could be 1/8th sphere geodesic domes. These are 80 foot in diameter in the drawing. This would sort of be a thick flying saucer shape. A small building on top lets people enjoy the view.

Internal

The geodesic shape should mean you don't need as much, or maybe any, internal bracing. This can open up the inside space and make it cheaper to build.

The living area might be 50 foot diameter with storage closets and emergency flotation foam in the thinner part around the living area.

Can easily have two floors inside or just one with a very high ceiling. Internal walls and floor do not need to be built the same time or with the same method as the hull and roof.

Other

Should be very strong, very stable, very safe, and not very costly for the amount of living space.

In a raft that is rocking back and forth in the waves the center has the least motion. In this design the people are closer to the center.

Windows would only be easy on the small building on top. Might use small strong glass to make portals to let some light in and let people see out some.

The heavy things like batteries should be at the very bottom of the inside space (say below a flat internal floor). The building on top should be light so that even if the main hull flooded it would still stay upright.

Could have 4 cables from around the outside going to a single HangingBallast well below the structure for added stability. The 80 foot wide base for the hanging ballast should make it very effective.

Materials

Probably best to use steel plates like normal ships. However, this could be done in aluminum. It would also be possible to do this in concrete. With concrete you could make a smooth section of a sphere. With metal you would use triangles of flat plates to make a geodesic dome.

The triangles and stiffeners would be easy things for regular shipyard robots to make. So this can be automated and done for a reasonable price.

Might make the triangles so that they could be bolted together. Bolting together could be done near the launch site by a small group with a crane in a few days. This would not be very costly. Might even ship the parts to another country before assembling. Could make it where we put a rubber gasket around each triangle and then bolted them together. The bolts would be put through stiffeners at the edges and completely inside. As they tightened the rubber would make the joint water tight even if there were some slight imperfections in the sizes of the triangles.

Might also just weld the triangles together like sections on a normal ship.

Steel plate at an angle makes for good armor. If the foam inside is squeezed it can even expand to fill any holes. If this has enough foam that it can not sink, pirates in a smaller sinkable boat would think twice before starting a fight (assuming they were detected).

Cost Estimation

Imagine we use 3/8-inch plate and enough siffeners that we average out to as much steel per square foot as 1/2 inch plate. Two 1/8th sphere sections will have 1/4 the area of a sphere. The area of a sphere is 4*Pi*R^2. The structure is 80 feet across and so has a radius of 40 feet, but that is not the radius of the sphere they are 1/8th the area of. This imaginary sphere has a larger radius, around 60 feet (trying to figure this out but this estimate will do for now). So the total area of the sphere is 4*Pi*60^2 = 45,238 sq-feet. The 2 parts of 1/8th sphere each will then total 11,310 sq-feet. If the steel averages 1/2 inch thick, then 24 sq-feet use up 1 cubic foot of steel. So the total is 11310/24=471 cubic feet of steel. Steel is about 490 lbs per cubic foot. So this structure would be 471*490=230790 lbs. From Cost estimation we see that steel ships cost around $1 per pound, so we can estimate a shipyard could build this structure for $250,000. This should be thought of as the incremental cost a shipyard would charge for building one more structure. Does not include any engineering, design, simulation, testing, or shipyard one-time-costs. Does not include internal floors/walls (which might not be made from steel or at the shipyard). Also does not include solar panels, furniture, windows, etc. Nor any profit for a company making these. Probably could produce these for between $500,000 and $1 mil.

Solar

Could have solar on one side of the roof and always rotate the whole vessel so that side was toward the sun.

Requirements Analysis

- Safety

- It is very wide compared to boats and so should be very stable

- Part is filled with foam so essentially unsinkable

- No active ballast controls so no chance of that going wrong

- Comfort

- Should have a gentle motion on normal days but significant response to large waves.

- A hanging ballast would reduce motion further

- Cost

- This should be one of the cheapest designs. It's very simple. The geodesic shapes mean it does not need much or any internal structure. Construction would be very similar to normal ships and so shipyard robots should be able to deal with it.

- Pretty

- Looks interesting.

- Modular

- Can make individual family sized units. Could have cable under a line of these so they floated together if you connected a sea anchor at one end and a large kite at the other.

- Cargo

- Since it floats up and down with waves like a boat, should be reasonable to dock a boat next to it.

- Free Floating

- Yes, could anchor also.

- Scalable

- Is small enough for one family. The shape could scale to much larger sizes. Geodesic domes scale well.

- Standards

- Mobile

- Will move through the water easier than most seastead designs but not as easy as a ship.

- Draft

- Very shallow draft for a seastead.

Alternatives

Could just have a geodesic hull and then a flat deck supported by columns and beams. So it is more like a round ship. With a bigger diameter, maybe 120 feet, the edges should be high enough above the sea that there would never be much water coming on deck.