Connections

This page is about connections between seasteads. They are an interesting feature from many perspectives. Instead of being yet another problem to worry about, they offer many interesting possibilities for making seastead design easier.

Contents

Logistics

On might argue that for small scale seasteads, connections are a logistical necessity. When on a big seastead with hundereds of inhabitants, one might stay on the same seastead for days on end. But when living on a seastead which is either an independent house, or a few of them, getting out of the house is likely to be something youd want to do multiple times a day. Transferring between vessels in the open ocean is hard to impossible, depending on the weather outside link. Getting groceries or visiting your neighbors is quite an ordeal if it involves twice boarding and twice docking your ferry boat; and it is not at all obvious what kind of ferry would survive being docked outside a harbor. Having a permanent system of walkways between seasteads is thus almost a logistical necessity.

Relative positioning

If relative positioning is taken care of by means of weak propulsion aimed at global positioning, this would be dangerous during storms, where we would not be able to guarantee that no collisions would happen.

By connecting neighboring seasteads with a properly designed construction, this problem would be solved more reliably.

Roll suppression

By connecting multiple seasteads, a cluster of seasteads is created, with a Sparse Footprint potentially much larger than that of any individual seastead.

Heave Supression

If one considers three seasteads connected into a triangle formation, (comparable to MiniFloat), no significant heave supression is to be expected. A desire for one corner to rise is not effectively supressed. If more than three seasteads are rigidly connected into one big cluster, significant heave supression will be achieved. Like a normal big footprint, such a large sparse footprint will average out the varying buoyancy forces around the cluster, resulting in reduced net heave. That is, if these connections dont break first. It brings back the same fragility problems as for a large dense footprint. The forces these connections would have to transfer in order to average out these fluctuations in heave are very large, and building such a structure in a way that it will survive worst-case storms seems impossible.

Flexibility

Connections between seasteads can be conceived of with various degrees of freedom.

Fully Rigid

As discussed above, this has limited applicability as far as modularity is concerned. Rigidly connectin a large cluster of seasteads is impossible, and flexibility will have to be facilitated in some way.

Fully Flexible

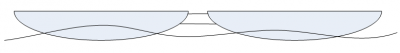

Offshore Access System As far as logistics are concerned, a fully flexible connection would suffice. In some situations, this would be the only possibility; unless a seastead was designed with connections in mind, it is unlikely to be able to handle the force of it.

Distance Fixing

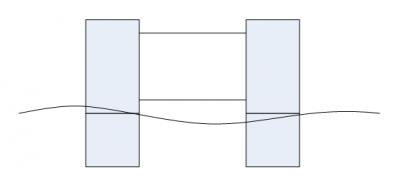

Single horizontal hinged connection

Distance&Roll Fixing

Double horizontal hinged connections

Damped

Distance&Roll Fixing, Roll damping, heave damping

Connectability

If the intent is for a seatead to be connectible to a cluster of other seasteads, this has strong implications for the design of said seastead.

A slender seastead (narrow and high) is easier to connect than a flat seastead (wide and low)

Slender column shaped seasteads are more easily connectible, for two reasons:

- By increasing the vertical seperation between connections, more moment can be transferred.

- A small footprint design has low coupling to the water with respect to roll motions.

Existing ships are likely only connectable with a fully flexible connection. Perhaps a single fixed length connection could be made to work, depending on the ship. Double hinged connections, as shown in the picture above, are definitely not an option. Either way, more or less permanent connections would negate the mobility advantages of a ship.

Connections have other structural implications. The loads that need to be transferred by these connections can potentially be quite high. A seastead with an 'exoskeleton', like a ship, is designed to handle mostly distributed loads: one cannot simply weld a connecting beam to it. By giving a seastead an inner steel skeleton, it becomes easier to dimension it such that it will be capable of handling any attached connections.

Energy

?